Thermal barriers, notably heat shields and cold air intakes (CAIs), are essential in managing extreme temperatures across industries. Heat shields insulate surfaces, reflecting or absorbing heat to maintain ideal temperatures and protect components from direct exposure. CAIs introduce cool external air into systems, cooling critical parts and enhancing performance. Effective thermal barriers leverage advanced materials like high-performance fibers and specialized coatings for optimal temperature control, ensuring system efficiency and extended component lifespans in challenging environments.

Thermal barriers play a critical role in managing extreme temperatures, from protecting machinery in high-heat environments to ensuring comfort in cold climates. This article delves into the science behind thermal barriers, exploring their fundamental principles and contrasting their applications in heat shields and cold air intakes. We analyze strategies to maximize effectiveness, highlighting various practical applications where these barriers are revolutionizing temperature regulation across industries. Understanding thermal barriers is key to navigating extreme temperatures, be it protecting vital components from scorching heat or preserving freshness in frigid environments.

- Understanding Thermal Barriers: The Basic Principles

- Heat Shield vs. Cold Air Intakes: A Comparative Analysis of Temperature Regulation

- Maximizing Thermal Barrier Effectiveness: Strategies and Applications

Understanding Thermal Barriers: The Basic Principles

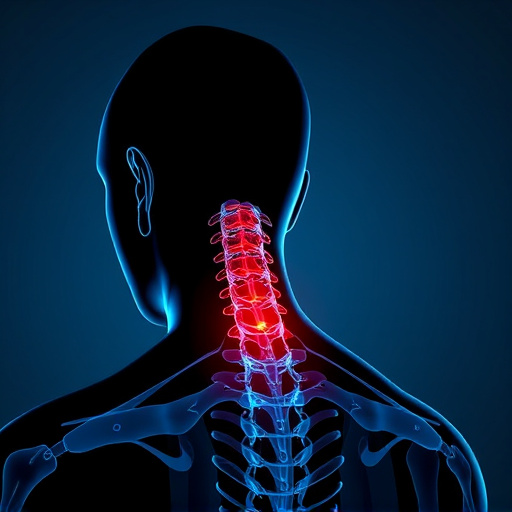

Thermal barriers are designed to protect systems and components from extreme temperatures, a crucial factor in many industrial and automotive applications. At their core, they function by creating an insulative layer that blocks or significantly reduces heat transfer. This is achieved through a combination of materials with low thermal conductivity, often combined with reflective surfaces to bounce heat away.

In the context of vehicles, for instance, heat shields are employed to protect cold air intakes from the engine’s intense heat, ensuring efficient airflow and maintaining optimal temperature control. By preventing heat from transferring into sensitive areas, these barriers enhance overall system performance and longevity, particularly in extreme environmental conditions.

Heat Shield vs. Cold Air Intakes: A Comparative Analysis of Temperature Regulation

In the realm of thermal management, the battle between heat shields and cold air intakes (CAIs) is a critical aspect of temperature regulation, especially in automotive and industrial applications. Heat shields, as the name suggests, are designed to protect surfaces from direct heat exposure, reflecting or absorbing excessive heat energy. On the other hand, CAIs are strategic openings or channels that draw in cooler external air, aiding in cooling internal components.

The effectiveness of these two systems lies in their contrasting approaches. Heat shields excel at retaining a desired temperature by isolating hot components from surrounding environments, preventing heat transfer. This is particularly useful in scenarios where maintaining high temperatures is essential, such as in engine compartments. In contrast, CAIs are game-changers when it comes to lowering internal temperatures, especially in extreme climates or high-performance engines. By drawing in cold air, CAIs enhance the cooling process, ensuring optimal performance and efficiency while mitigating the risks associated with overheating.

Maximizing Thermal Barrier Effectiveness: Strategies and Applications

Maximizing Thermal Barrier Effectiveness involves strategic approaches tailored to specific applications, especially in systems managing extreme temperatures. One key strategy is incorporating advanced materials designed to reflect and insulate heat, like high-performance fibers or specialized coatings. These materials play a crucial role in thermal barriers by creating an effective heat shield, preventing hot air from penetrating and cold air intakes from losing their chilling effect.

In applications demanding optimal performance, such as automotive cooling systems or aerospace components, the arrangement of these thermal barriers is just as important as the material choice. Precise design considerations include ensuring complete coverage, minimizing gaps, and managing heat flow dynamics. This meticulous approach allows for unparalleled temperature control, enhancing system efficiency while prolonging the lifespan of critical components subject to extreme heat or cold.

In understanding thermal barriers, their basic principles, and exploring applications like heat shield and cold air intakes, it’s evident that maximizing temperature regulation is key in various industries. By employing strategic techniques to enhance thermal barrier effectiveness, we can optimize performance while minimizing energy loss. The interplay between heat shields and cold air intakes demonstrates the importance of thoughtful design and materials science in managing temperature, ensuring efficient systems across diverse sectors.